Previous Index Next

Rosette Inlaying

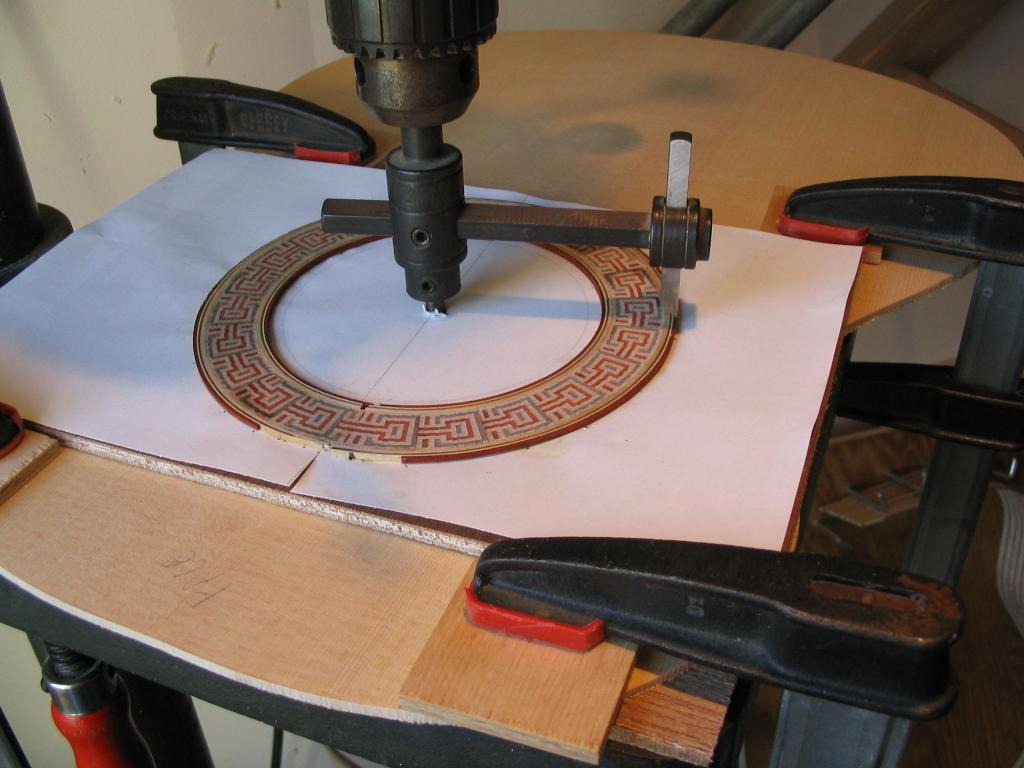

The rosette is inlayed by cutting a groove in the guitar top that

exactly fits the assembled rosette, and then gluing the rosette into

the groove with epoxy. The outer and inner edges of the groove are cut

with a flycutter on the drill press. The principal trick is in getting

the size of the groove so that the rossete fits perfectly. This is done

by setting the flycutter directly from the rosette. The rosette, still

glued to its building board, is place on the drill press. Since the

flycutter was used to cut the inner and outer edges of the rosette

(before the rosette banding was glued on), the 1/4" guide hole for the

flycutter is used to center the building board on the drill press. The

flycutter diameter can then be set from the rosette, as illustrated.

Note that a flycutter is an inherently dangerous tool - it's a fairly

heavy, unbalanced mass of rotating steel. Be sure to protect yourself

when using it. I wear a complete facemask protector; I've even heard of

someone putting a phone book into his shirt as a chest protector.

Always use the flycutter at the slowest speed available on the drill

press, to minimize the centrifugal forces. And because it's so

unbalanced, don't even think about using one in a hand drill!

Note that in the photograph, the rosette building board is placed

directly on the guitar top into which the groove will be cut, for

convenience. The cutter diameter is set, and the rosette building board

is removed. The depth of cut of the flycutter is set to be a little

less than the thickness of the rosette, so that the rosette will sit a

little proud when glued. The excess can then be scraped off, leaving

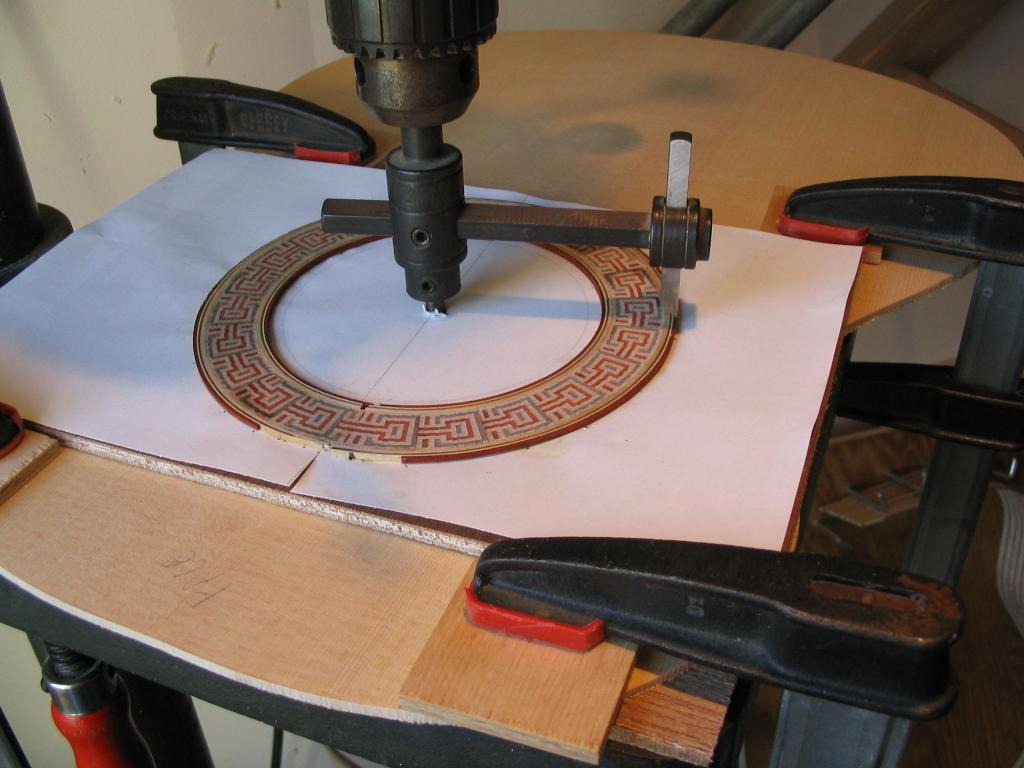

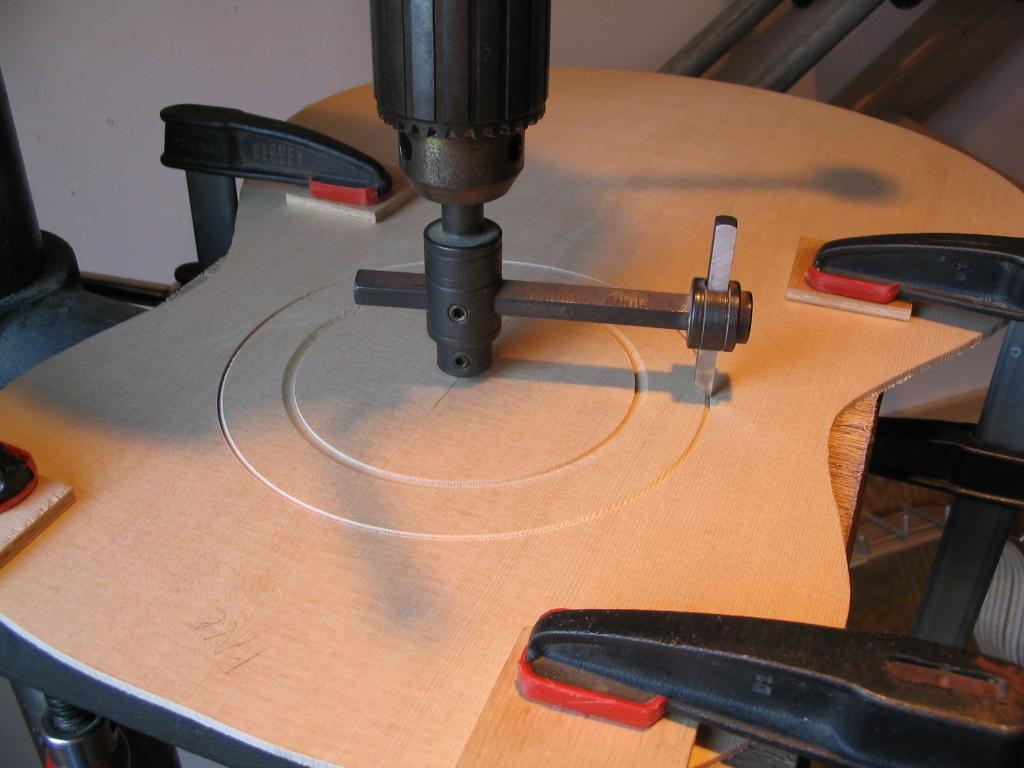

the rosette flush with the top. The next photo shows the grooves cut in

the guitar top. Note that the soundhole is not cut until after the

rosette has been glued and scraped.

After the inner and outer radii have been cut with the flycutter, the

remainder of the material in the groove can be removed with a router,

with the depth set appropriately. The groove can then be cleaned up

with a chisel.

The rosette should now be removed from the building

board. Since it was glued onto the board with a sheet of paper in

between, the rosette can be relatively easily removed by sliding a thin

blade between the rosette and board - the paper will split fairly

easily.

The paper that remains on the rosette can be removed with a

scraper.

The inner and outer edge of the rosette banding should have

their edges chamferred (beveled) slightly so the rosette can be pressed

into the groove. The rosette ring should now be cut to permit easier gluing into the groove in the top.

The groove in the guitar top and rosette are shown in the next photo.

In preparation for gluing, the groove is next sprayed with a couple

coats of shellac. The purpose of the shellac is to seal the end-grain

on the edges of the groove near the centerline of the top. If this

isn'e done, the epoxy used to glue the rosette will wick into the

endgrain, discoloring the spruce near the soundhole. You don't have to

be careful when spraying the shellac, as the overspray on the top will

disappear during finishing. (However, if you don't use the shellac, the

epoxy staining doesn't disappear even under the finish - discovered

this the hard way...)

Why not use Titebond instead of epoxy? Wouldn't this eliminate the

problem of the glue staining the top through the endgrain? Well, yes,

but the problem is that the rosette is itself mostly endgrain. If

yellow glue is used, the tiles in the rosette tend to expand due to the

moisture in the glue, warping the rosette and even the top.

The groove can now be coated with epoxy - either 5 minute or longer

cure time will work fine - and the rosette pressed into the groove. The

top is placed on a flat workboard, a piece of plastic wrap is placed

over the rosette, and a piece of 3/8" or 1/2" thick plexiglass is

placed on this as a clamping caul. The rosette is then clamped and left

for the glue to cure, as in the next photo. The plastic wrap keeps the

epoxy from sticking to the plexiglass caul.

When the glue has cured, the clamps and caul can be removed. You can

see in the photo below the shellac overspray and the epoxy squeeze-out.

The rosette rises a little above the surface of the top; this is next scraped flush (along with the epoxy squeeze-out).

After the rosette has been scraped flush, the soundhole can be cut with the flycutter on the drill press.