The lower portion of the taper is sawn first.

Then the peghaed outline is cut, and smoothed with a spokeshave and rasp.

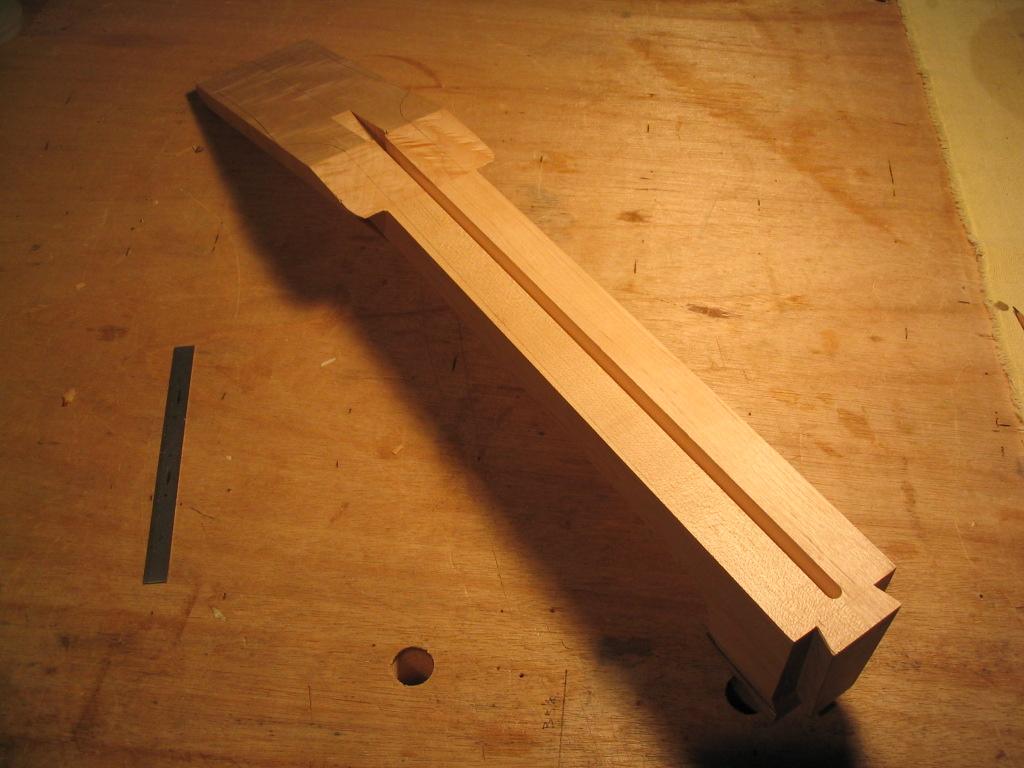

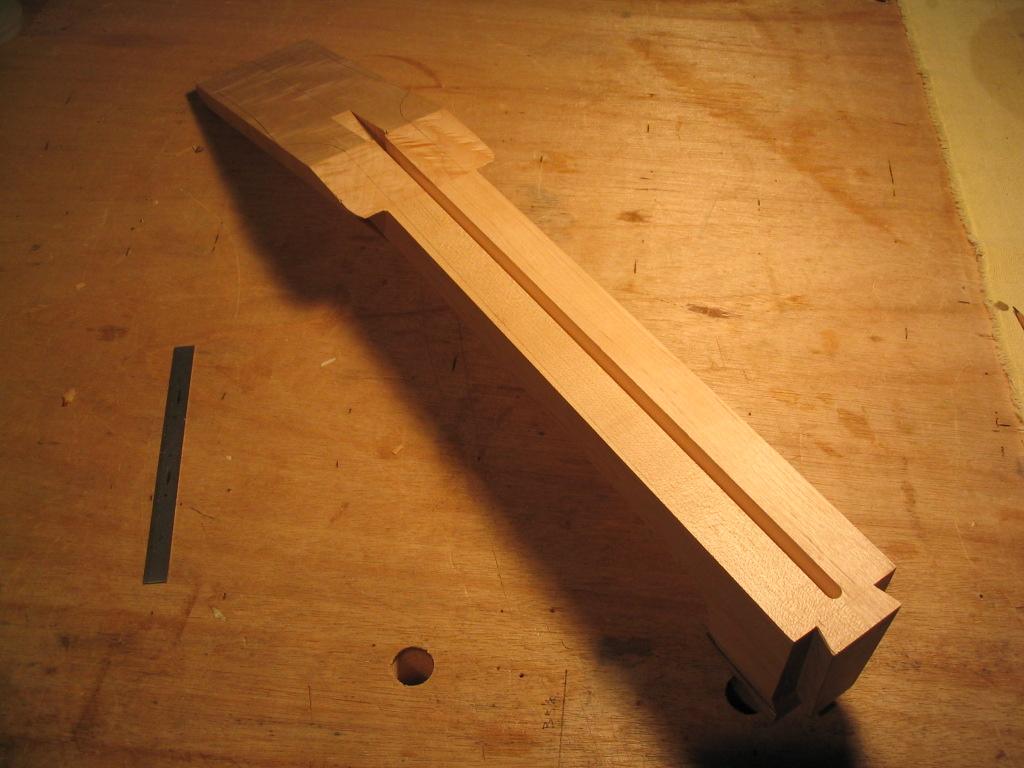

The taper on the neck is now finished

with a plane and files; the file is needed since the curve of the

peghead will prevent the plane from reaching that end of the fretboard.

The sides of the taper should be made absolutely straight.

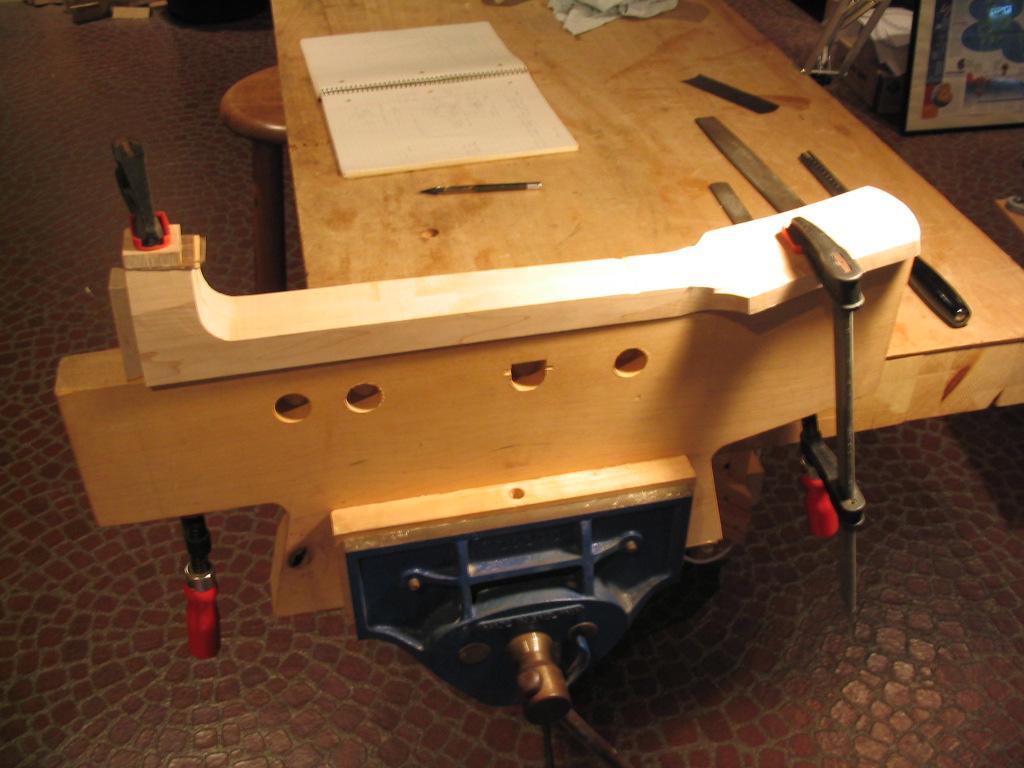

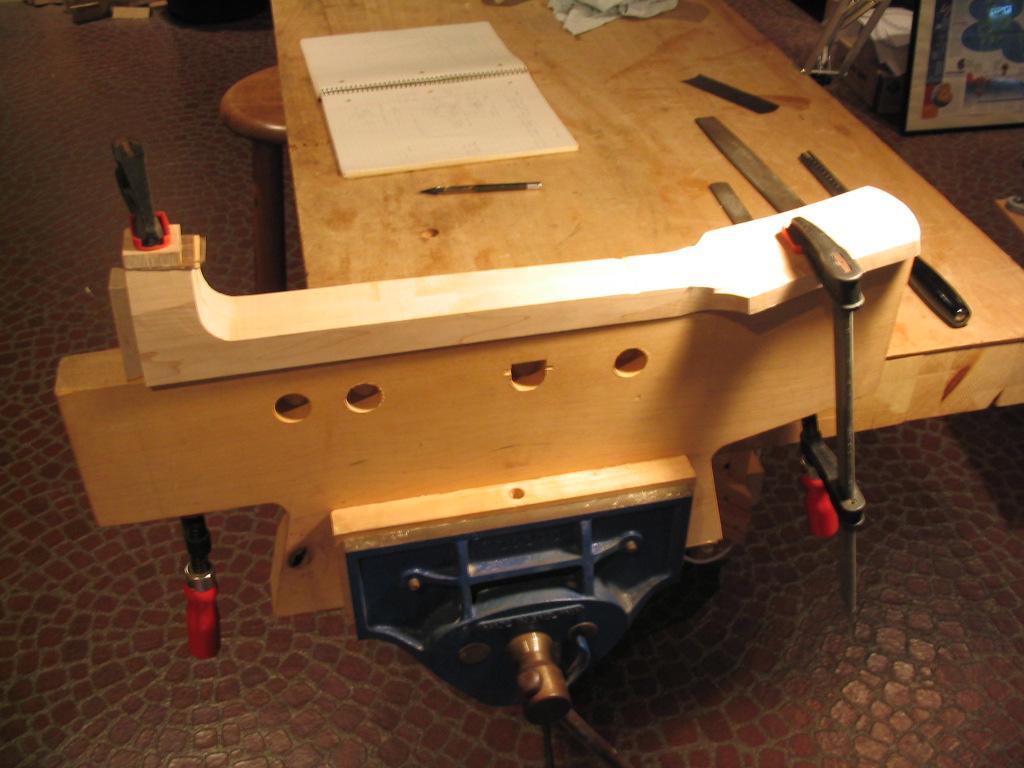

For carving, the neck is clamped to a carving jig. There's a wedge underneath the peghead to support it.

The neck thickness is first established

at the 2nd and 10th frets by cutting grooves at these positions to the

correct depth. For this neck, I'm using thicknesses of .550" at the 2nd

fret and .600" at the 10th fret.

The neck thickness is measured as the

groove is deepened. The hole underneath the groove position is exactly

1" from the top surface of the jig to make measurement easier.

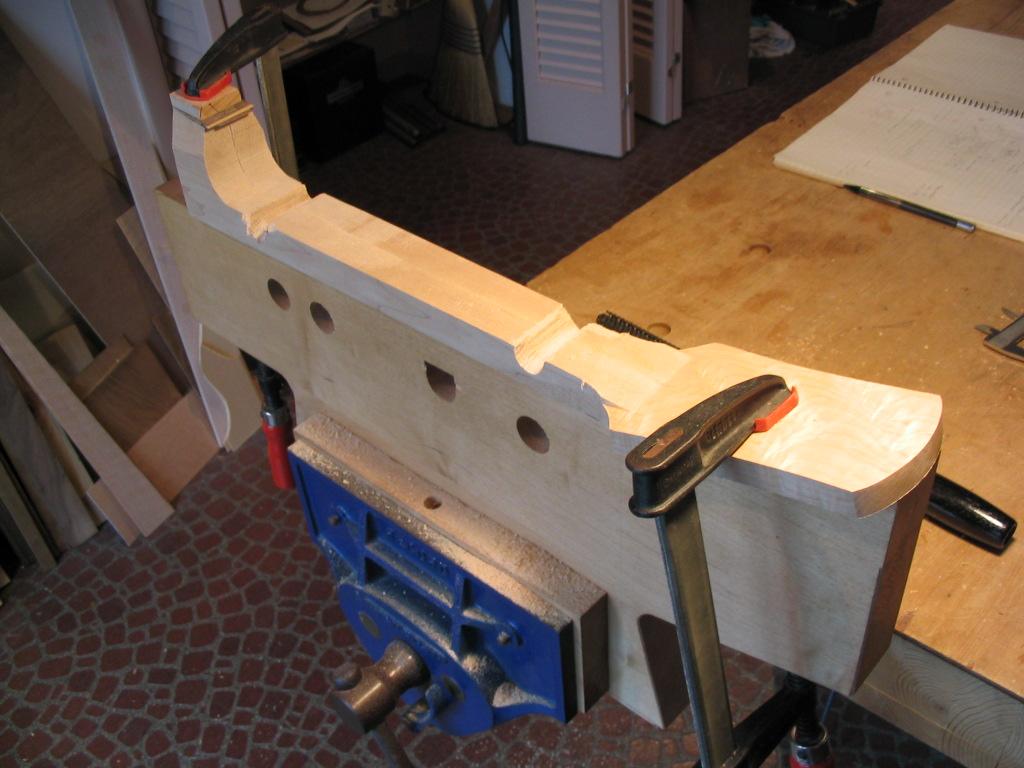

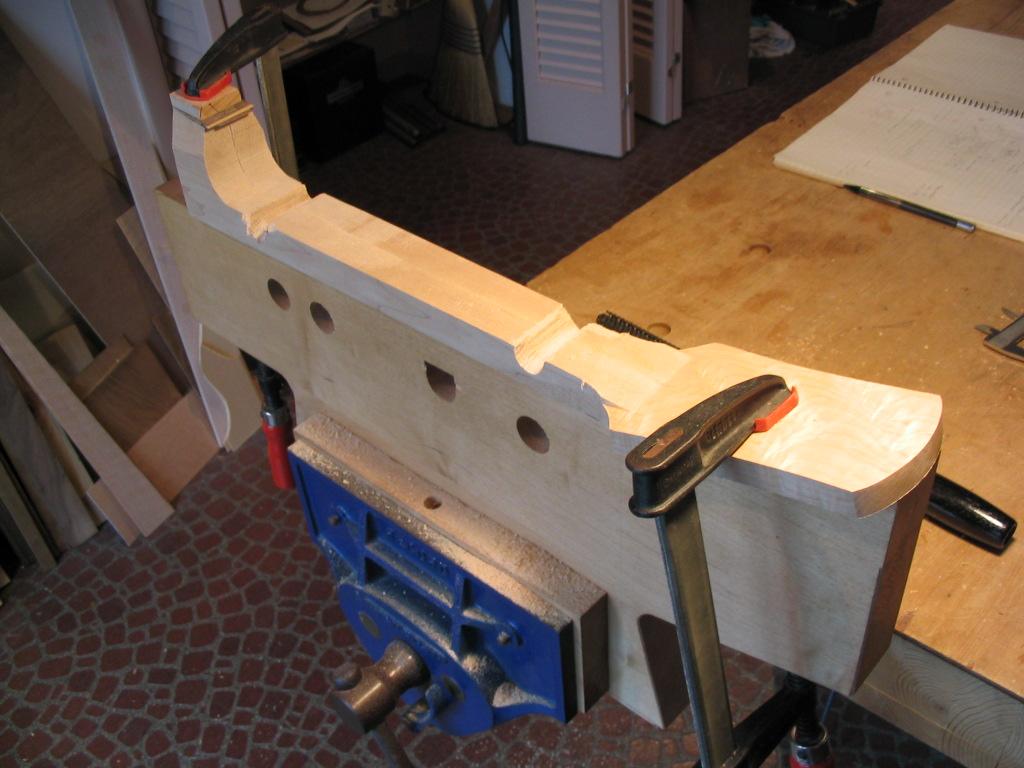

The neck after the grooves have been cut

- ugly, but the depth references are important to ensure the neck is

thinned to the correct thickness.

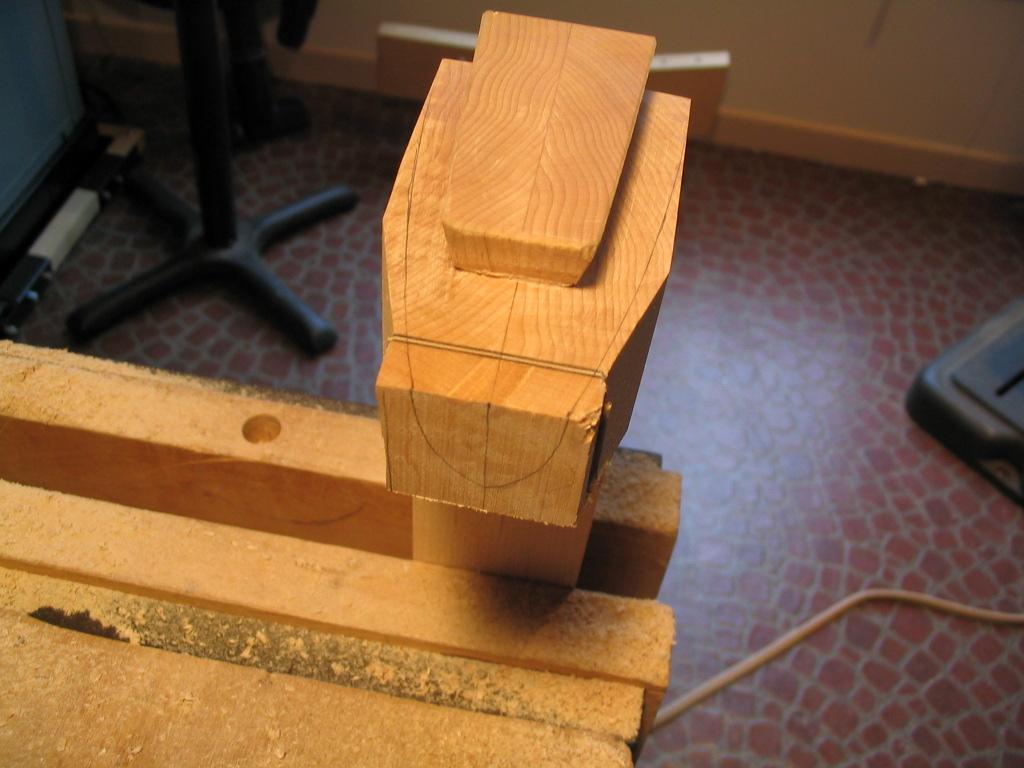

I then lay out a pattern for a

curved-diamond detail on the underside of the neck-peghead joint, below

where the trussrod groove ends. This helps to strengthen the neck in

this area, and provides a nice sculptural detail.

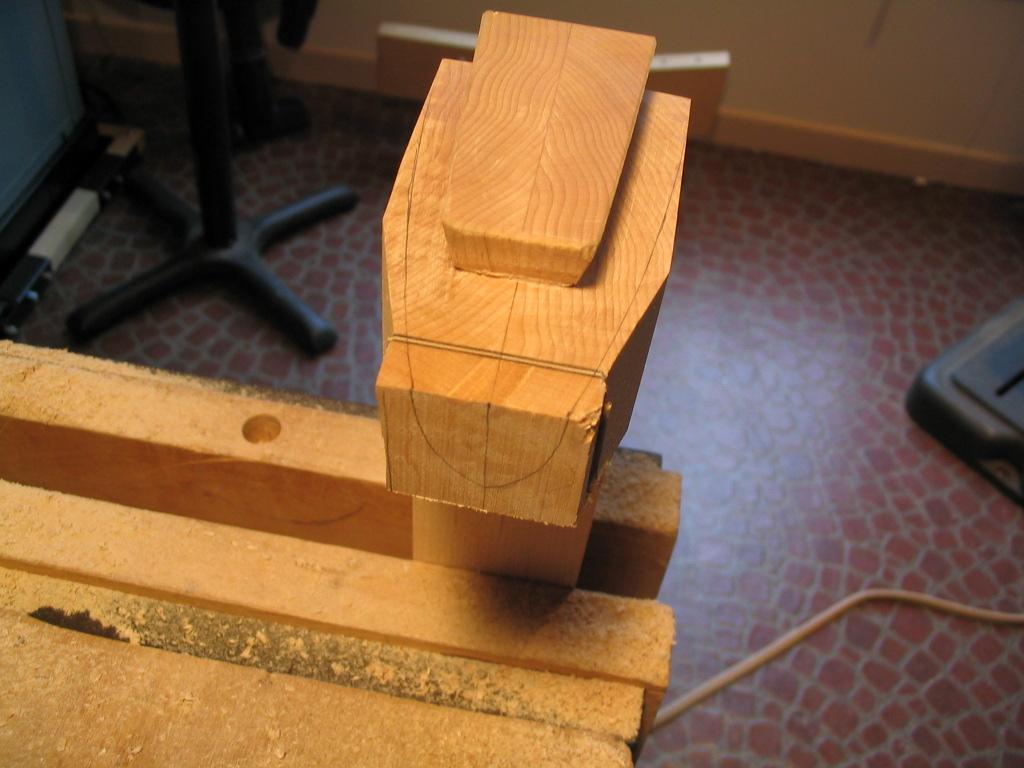

The heel profile is marked on the heel of the neck blank.

The neck is now thinned with a drawknife and spokeshave. The neck is thinned linearly between the two grooves.

The neck taper is checked to make sure the surface is straight between the two grooves.

The heel is rough-shaped with a bow saw, then shaped with drawknife, chisels, rasps and scrapers.

The peghead diamond detail is trimmed next.

The neck is shaped further by carving

facets on either side. The facets here are 11/16" wide, and extend down

to 3/16" from the top surface (i.e., there's a 3/16" facet left on the

sides of the neck).

The neck is finally smoothed between the facets with a spokeshave.

The peghead diamond shaping is completed, merging it with the neck.