Previous Index Next

Top Bracing

The top has braces glued on the underside, both to give the top extra

strength - the "X" brace and upper-bout struts - and to improve the

tone of the resulting instrument. The photo below shows the underside

of the top with the position of the X brace and upper bout cross brace

lightly marked in pencil.

The X brace legs must have the lap joint cut before gluing; the joint

is marked using an angle gauge since the braces don't meet at a right

angle. The joint is then cut in each leg with a dovetail saw, and then

pared with a chisel to get a tight fit. (If you're good with the saw,

paring may be unnecessary, but make sure to get a tight joint.)

The photo below shows the completed X brace, with joints cut. The legs

are glued together when the brace is glued to the top. Notice how the

top surface (which will be glued down to the top) is arched.

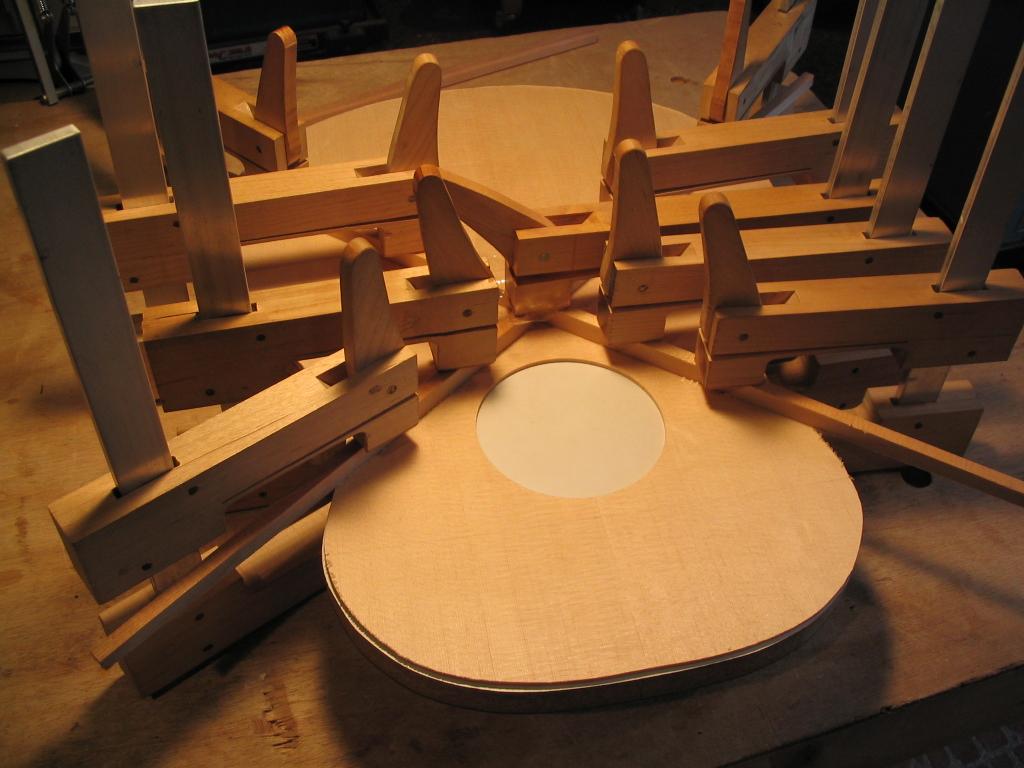

The X brace is being glued to the top, below. Glue has been applied to

the joint faces as well as the brace surfaces. The top is placed on an

arched workboard whose arching matches that of the braces. Here's an

article on how to make such an arched workboard.

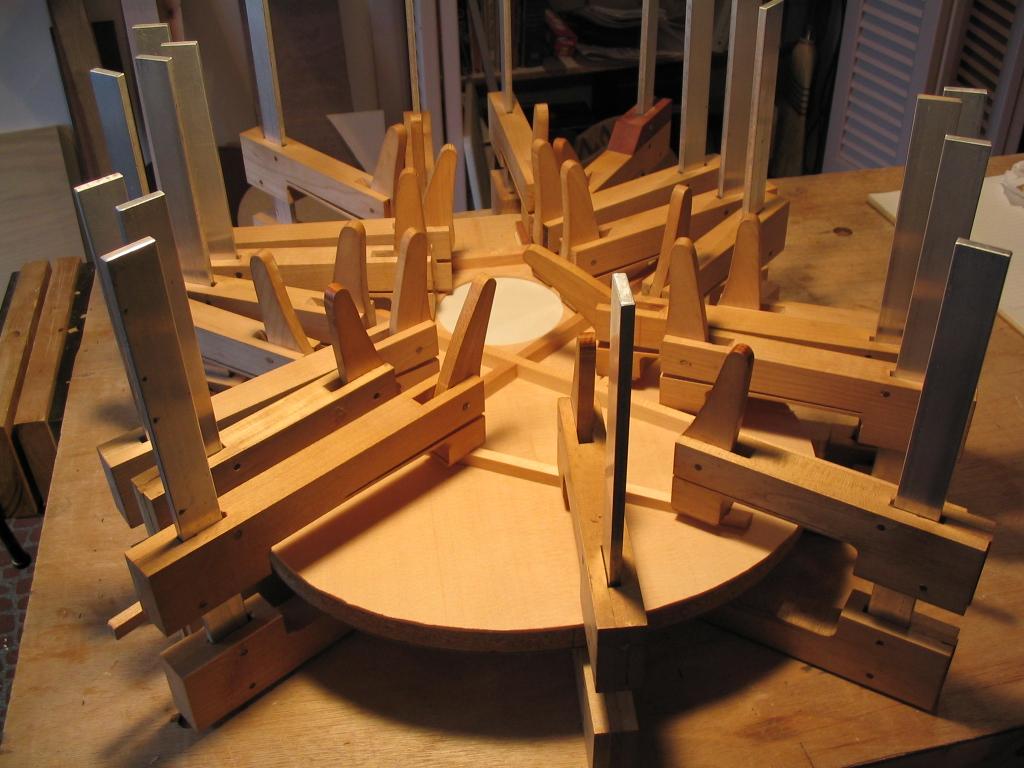

The photo below shows additional braces being glued to the top.

Below, the bridge plate is being glued (this one is .100", made of dogwood).

The top with all braces glued, but unshaped, is shown below.

The next few photos show the braces after rough shaping with a sharp

chisel. Note the tapering on the braces; they're tapered to a thickness

of approximately .090" at the ends, and are tapered bottom to top.

After rough shaping, the braces are sanded to smooth the surfaces. The

result is shown in the photos below. Note that the ends of the braces

have been trimmed where they meet the periphery; they're trimmed to

within the thickness of the sides from the edge.

Previous Index Next

Comments/questions: jsevy@cs.drexel.edu