Fretting

The frets on a

guitar are strips of specially shaped wire with a "T" cross-section,

whose "tang" fits into the fret slots cut in the fretboard. The tang

has small bumps or barbs on its sides. The traditional way of affixing

the frets to the fretboard is to cut the slots to the width of the tang

without the barbs; the frets are then hammered into the slots, and the

barbs grip the sides of the slot to hold the frets in. Unfortunately,

the barbs not infrequently lose their grip, and the frets

pop out of the slots, leading to buzzing while playing. Epoxy adhesives provide an alternate method for attaching the

frets: the slots are cut to the width of the tang plus the barbs, and

the frets are glued in with epoxy. The epoxy forms a little casting

around the barbs, and thus holds the frets firmly in place, eliminating

the tendency for them to pop out of the slots. The following illustrates this epoxy fretting method.

Surprisingly, the epoxy fretting method makes fret removal easy when it

is time for the guitar to be re-fretted when the frets have become

worn. Epoxy loses its strength when heated, so the frets are easily

pulled from the fretboard if they are each first heated. This is accomplished with a

soldering iron run back and forth across the fret surface. The epoxy

which remains in the slot is then removed with a fine bit in a Dremel

tool. With the traditional method, the barbs have a tendency to cause

the fretboard to chip at the edges of the slots when the frets are

pried from the fretboard; this doesn't occur with the epoxy fretting

method, since the width of the slot includes the width of the barbs.

The fretboard is prepared for fretting by being surfaced so that it is

straight along its length and arched across its width. To achieve both

ends, a sanding block is used that has the desired convex arch across

its width. The block is shown below, made from layers of plywood

laminated together into the desired arched profile and faced with

Formica.

A plastic protective mask is placed on the guitar top to protect it during surfacing and fretting.

The surfacing of the fretboard is begun using very coarse sandpaper -

40 or 60 grit. As the fretboard is surfaced, the outer edges will be

cut first due to the curved profile of the sanding block. Pencil

"witness lines" are drawn across the fretboard, which disappear when

the sandpaper has cut the complete arched profile. The lines can still

be seen in the middle of the fretboard in the photo below, indicating that the arching is

not yet complete (the center of the fretboard is still flat).

The straightness of the fretboard is checked with a straightedge

as surfacing progresses. I try to get the fretboard perfectly flat;

some builders put a little "relief" in the fretboard, surfacing it so

there's a little space under the center of the straightedge, i.e., so

the fretboard is curved up slightly.

When the fretboard surfacing is complete at the coarsest grit, the

surfacing continues with a succession of finer grits up through 220

grit. Pencil witness lines are drawn at each stage to make sure

the scratches left by the previous grit are removed by the next.

The final sanding is done by hand with 320 grit paper, followed by

polishing with steel wool. I then apply a light coat of a mixture of

linseed oil and varnish, which makes it easier to remove any epoxy

squeeze-out after the frets have been glued. It's important to make

sure none gets into the fret slots, where it would interfere with the

adhesion of the epoxy used to attach the frets.

The fret wire is usually supplied in straight 2-foot lengths. I curve

each length of fret wire into the desired arch to match the profile of

the fretboard, since it's easier to bend the long piece of wire before

it's cut into appropriate lengths for the frets. The curving is

facilitated with a block with a curved top surface and a groove for the

fretwire tang to fit into; the block is illustrated two photos down.

The pre-curved fretwire is then cut into appropriate lengths, with each

fret being slightly longer than the corresponding fretboard width.

Because the fretboard has binding along the edges, each fret must have

its tang notched at the ends so the top surface will extend onto the

binding. This also illustrates the block used to curve the fret wire

into an arch corresponding to the fretboard arch.

The fret shown notched to fit within the binding.

The notched frets laid (but not yet glued) in the fretboard.

I next chamfer the top corners of each fret slot, using a bent file.

This helps to prevent any chipping at the edges of the slots when the

frets are removed, which occasionally happens with the epoxy fretting

method is the slot is a little too narrow.

The edges of the fretboard are taped to catch any epoxy squeeze-out from the ends of the frets.

The frets are then placed in the fretboard, and masking tape is applied

between the frets to keep epoxy from getting onto the fretboard. Some

luthiers don't bother with this taping, instead cleaning and scraping

the fretboard after gluing in the frets.

The frets are clamped into place when glued using a special clamping

caul. The caul is consists of 1/4" Plexiglass tapered in width to match

the fretboard, with Plexiglass strips along the edges and a cork strip

in the middle. The caul thus applies pressure at the outer edges of

each fret where the Plexiglass edge strips contact, and at the middle

from the pressure of the cork.

Epoxy is mixed and spread into the fret slots. The frets are then

placed into their slots, and any squeeze-out is wiped off with a paper

towel dampened with denatured alcohol.

A sheet of plastic wrap is placed over the frets to keep the epoxy from

contacting the clamping caul, and the caul is placed onto the frets.

A solid caul is placed over the flexible Plexiglass caul, and the frets

are clamped into the fretboard. Note that the protective mask has been

removed from the top to allow access to the soundhole for clamping.

When the epoxy has set, the clamps and cauls are removed, and the fret

ends are trimmed to the width of the fretboard. The ends of the frets

are trimmed flush and angled with a file.

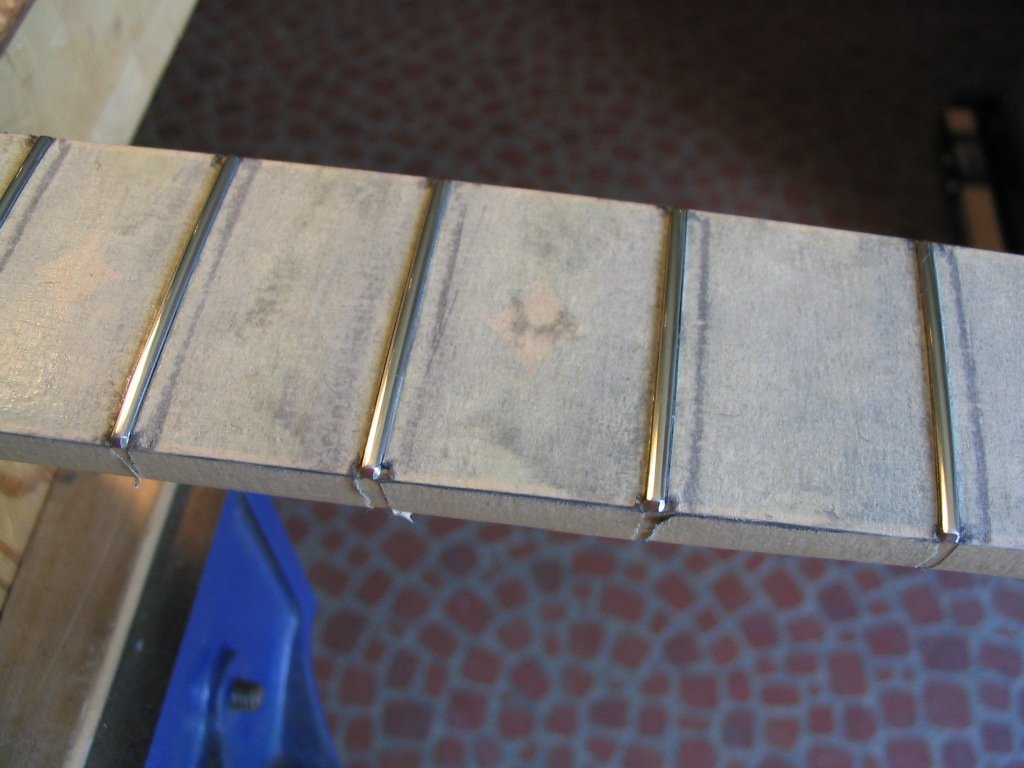

The fret tops are leveled with a sanding block with 320-grit sandpaper

glued to the face with spray adhesive. Leveling starts at the body end

of the fretboard, and continues to the nut. The frets are surfaced

until each shows a flat on its top, which indicates that the the frets

are all at the same level. The flat appears as the shiny stripe on the

fret in the picture below.

The edges are taken off of the flat on each fret using a block with a

V-groove cut in it. Sandpaper is held over the groove, and the groove

is run along the top of each fret, which rounds off the sharp edge of

each flat without taking material off of the top of the fret. In the

photo below, a narrow flat can still be seen on the crest of each fret

after this operation.

The fret ends are filed to remove the sharp points at the corners.

The frets are then polished with successively finer sandpaper, starting

with 320-grit and going to 600-grit. The same number of strokes are

used on each fret to ensure they stay at the same height.

The frets are finally polished with fine steel wool.

The masking tape is removed, and any remaining epoxy squeeze-out is

removed from along the frets edges with a sharp chisel. The fretboard

and frets are then polished with fine steel wool, and a final coat of

oil and varnish mixture is rubbed into the fretboard.

Previous Index Next

Comments/questions: jsevy@cs.drexel.edu