The guitar is now just about completed. Just a few additional fabrication steps are needed: installation of the neck reinforcing truss rod and cover plate, installation of the tuning machines, fabrication of the nut and saddle, and attachment of the pickguard.

Truss Rod

The truss rod is a reinforcing rod that is placed in the neck of a guitar to help to counteract the tendency of the strings to cause the neck to “bow” or arch toward the fingerboard. The strings place a great deal of tension on the neck – for light gauge acoustic guitar strings in standard tuning, the strings exert approximately 150 lbs of force on the neck. Since the strings pass over the fretboard and are consequently offset from the centerline of the neck, they cause the neck to bow slightly, just as the string of an archer’s bow causes the bow frame to curve. For an archer’s bow, this bending is of course the desired effect, but for a guitar a significantly bowed neck makes the instrument difficult to play as the strings will be high above the (arched) fretboard and consequently difficult to push down onto the frets.

However, paradoxically, a slight bow in the neck is actually desirable to allow the action to be set low without the strings “buzzing” on the frets. When the strings vibrate, they naturally move more in the middle of the strings than at the ends, since the ends are fixed at the nut and saddle. In fact, the motion of the string forms an almond-shaped “envelope” from end to end, with the ends being motionless (resting on the saddle and nut) and the center moving up and down the most. As the string flexes up and down, it will be curved up when it’s at its highest point (furthest from the fretboard) and curved down when it is at its lowest point (closest to the fretboard). It is at this low point that the string can hit the frets and cause a buzz. A slight bow in the fretboard can keep this from happening by having the fretboard arch match the curved envelope of the vibrating string. This slight arching of the fretboard is called relief, and can be seen by sighting down along the fretboard from the peghead. On a properly set up instrument, the frets will be seen not to lie exactly in a plane, i.e., the fretboard will not be perfectly flat.

Thus the string tension actually does something that we want – putting relief into the fretboard – but will generally induce too much bowing. The trussrod is intended to counteract the tendency of the strings to bow the neck, and create just the amount of relief that we want (more on the correct amount in the section on setting up the instrument). Two different types of truss rod have been used: fixed and adjustable. A fixed truss rod is just a stiffening rod embedded into the neck to help keep it from arching when the strings are brought up to tension. While this will help keep the strings from putting too much bow into the neck, it provides no adjustability if the amount of bow isn’t exactly as desired. An adjustable truss rod applies a bending force in the neck that opposes that of the strings by tightening a screw or nut. Adjustable truss rods can further be subdivided into “one way” and “two way” adjustable rods. A one way adjustable rod can only apply force to counteract the bending applied by the strings, while a two-way rod can apply a force in either direction, to bow the neck either up or down. The latter is useful in cases where the strings don’t exert enough force to put sufficient bow into the neck to give us the relief (arching) that we need to prevent the strings from buzzing; in this case a two-way rod can actually help the strings to put a little additional bow into the neck. But this is usually necessary only if the neck has warped to take on a “back bow”, or if the neck is too heavily built to begin with.

I have previously made and used a one-way adjustable rod, since I build relatively thin necks that the strings have no difficulty putting plenty of bow into with their natural tension. However, I’ve recently switched to using a commercially-available two-way rod, primarily because it’s one less component to make and actually requires a simpler truss rod groove. However, for completeness, the appendix describes how to make a one-way truss rod.

Tuning Machines

The installation of the tuning machines is straightforward; the only trick is to do a little reaming of the holes drilled in the peghead to remove any finish that has gotten into the hole during the finishing process.

Bridge Pin Fitting

The pins used to secure the string ball-ends to the bridge need to be fitted to the string holes in the bridge. Since each pin will vary slightly in diameter, particularly ebony or other wood pins, it is necessary to ream each hole to fit its specific pin and then keep each pin associated with its hole until the strings are installed. The holes are reamed with a tapered reamer whose taper matches that of the pins. Each hole is reamed until its associated pin seats tightly with a firm push.

The front edge of each hole can then be relieved with a knife to break the hard edge where the string will pass over. The front side of the hole will also need to be notched to allow the string to pass between the pin and the hole – while the pin has a notch cut along its length for this purpose, it’s usually not sufficiently deep to allow the pin to be pushed all the way down when the string is installed. The notch will naturally be bigger in the holes for the larger (lower-pitched) strings.

Nut

The nut and saddle are the pieces that support the strings at the end of the fretboard and the bridge, respectively. The nut in particular is notched to hold the strings at the appropriate spacing from one another. The saddle is usually not notched as the pegs holding the strings to the bridge provide the spacing. However, the height at which the strings are supported is important at both the nut and saddle; for the nut it’s the depth of the string slots that determines this height.

The nut and saddle are generally made of very hard material to resist the tendency of the steel strings to dig in. The traditional material is bone, but ebony, brass and even some plastics like Corian are also used. Rectangular bone nut and saddle blanks are readily available from lutherie suppliers such as Luthiers Mercantile.

To make the nut, a rectangular blank approximately 2″ long by 1/4″ wide by 1/2″ high is used. (The one shown is from a raw piece of bone and shows a “divot” at one end where the inside surface of the bone is.)

The peghead veneer needs to be trimmed so the nut will fit between it and the end of the fretboard while sitting flat on the neck surface. This trimming is done using an angled block to guide the saw and keep it perfectly vertical while cutting. The block is positioned by placing the nut blank between the block and the end of the fretboard.

The blank is then removed and the peghead veneer carefully cut away, using the block as a saw guide and being careful not to cut into the neck material.

The peghead veneer slot after cutting.

The nut blank is then placed into the slot between the end of the fretboard and the peghead veneer for marking. The ends are marked so they’ll be flush with the sides of the fretboard. The top surface should be roughly parallel with the curved top of the fretboard, but above it to allow for the string grooves. This profile can be conveniently marked with a “half pencil” that’s cut down the middle so that as the flat surface of the pencil rides on the frets the point will trace a line at exactly that height on the nut. A modified carpenter’s pencil is shown below.

The line being marked is at the fret height, which is the reference mark for the bottom of the string slots. I put a thin piece of veneer or plastic on top of the frets to draw a second line parallel to and slightly above this to mark the curve for the top of the nut.

The nut is then cut and shaped using a hacksaw, files and sandpaper to the desired profile. When the shape is correct, the nut is glued into the slot in the neck using a couple of drops of cyanoacrylate glue. The shaped and installed nut is shown below.

At this point the string slots must be cut. The strings should be evenly spaced, with about a half-spacing at either side of the outer strings. These can be calculated and marked with a ruler; for convenience, I print out a set of lines with the desired spacing from a CAD program and glue a strip of paper with these spacing lines onto the nut top surface.

The string slots can then be cut with a series of fine saws and files. The depth of the slots should be just above the reference line traced with the flattened pencil riding on the fret surfaces. It’s actually important not to cut them too deep, or the strings will buzz against the frets. The final depth adjustment can easily be done once the strings are installed, as described below, so at this point the slots are left a bit high, i.e., are not cut quite down to the pencil mark. The width of the slots should be equal to the width of the string that passes through it, which means the string slots get wider as you go from the treble to the bass strings. The slots should also be angled back at approximately the angle of the peghead.

Saddle

The saddle is fabricated from a bone blank 1/8″ thick by approximately 1/2″ wide and 3″ long. The length of the blank is cut to fit into the slot routed into the bridge, including rounding the ends. To get an initial profile for the saddle, it is placed in the bridge slot, and the top profile is marked on the blank using a stick with a pencil at the end that works like the flattened pencil used to mark the nut: the stick slides along the frets and the pencil marks the saddle blank top profile. The photos below show the saddle scribe in use. The pencil is mounted in the scribe such that its tip is flush with the bottom of the scribe, so it marks the saddle with the The blank’s top edge is then cut a little above this profile (to leave room for final adjustment, as described next) and rounded to ease the strings passing over.

I’ve sometimes used an initial temporary saddle made of inexpensive material (plexiglass or the like) and left a little overheight. This temporary saddle will be replaced by the final bone saddle when the appropriate height is determined.

String-up and Adjustment

The guitar is finally ready to be strung up. The strings can be installed with the bridge pins, attached to the tuning machines, and brought up to pitch. This is the point at which the instrument will finally play its first notes and chords. However, there will probably be a need for some adjustments. In particular, the action – the height of the strings above the frets – should be too high since we deliberately cut the saddle too high. The neck relief – the amount the neck deviates from a perfectly flat plane – will also likely be too great, since we haven’t tightened the truss rod yet. Finally, the nut slots may not be the right depth, causing notes fretted near the nut (for “open” chords, for example) to be difficult to push against the frets. These parameters can be adjusted to provide an optimally playing instrument.

Nut Adjustment

The nut slot depths should really be such that the strings are supported at a height that exactly equals that of the nearest frets – i.e., the nut should be like just another fret, at least as far as the string height is concerned. In fact, some builders use a “zero fret”, with the nut behind it; the nut provides the string spacing while the zero fret provides the correct string height. However, it’s also common to make the string heights at the nut slightly higher than that of the nearest frets to allow a little more space to help prevent buzzing against the frets when open strings are played, as these tend to be strummed harder than fretted notes.

Checking the nut-slot depths is actually quite easy: just fret each string at the 3rd fret, and look “behind”, between the 2nd fret and the nut. The string will be pressed against the 2nd fret and pass over the nut, with the 1st fret in between; the nut-slot depth is correct if the string just barely touches the 1st fret, or if there is a very small gap (say, .005″ or less) between the string and the 1st fret.

If the distance is too great, the nut slot depth should be increased. If there’s not enough space – i.e., the string presses down on the first fret – the nut slot needs to be filled to raise the slot depth. However, I’ve not found a completely satisfactory way to do this, so I will usually just make a new nut. Since this involves a fair amount of work, I’m generally careful nut to cut the slot depths too deep, leaving them slightly high until this adjustment stage.

Truss Rod Adjustment

The truss rod is next adjusted to get the neck relief to the right state. As discussed above, it’s desirable for the neck not to be perfectly flat, but instead to have a small amount of “bow” or relief. However, the tension of the strings generally puts a little too much relief into the neck – the strings will tend to bow the neck more than is desirable. The truss rod counteracts the pull of the strings to bring the relief back to the desired value.

The relief can be evaluated by using the string as a straightedge to measure the bow in the neck. The high E string is fretted at both the 1st fret and 12th fret; the relief can then be seen by the fact that the string doesn’t touch each of the frets in between.

Because of the bow in the neck induced by the string pressure, the frets between the 1st and 12th will be seen to “curve away” from the straight string, with the largest space between the string and frets occurring about half way between, at the 5th or 6th fret. This maximum space gives a way to measure the amount of relief; I generally adjust the truss rod so the space between this “middle” fret and the string is about .010″, or about the thickness of the high E string itself.

The relief can be varied (by adjusting the truss rod) to accommodate different playing styles. A lower relief will suit softer playing and fingerpicking, while a higher relief can better accommodate harder playing and strumming.

Saddle Adjustment and Action

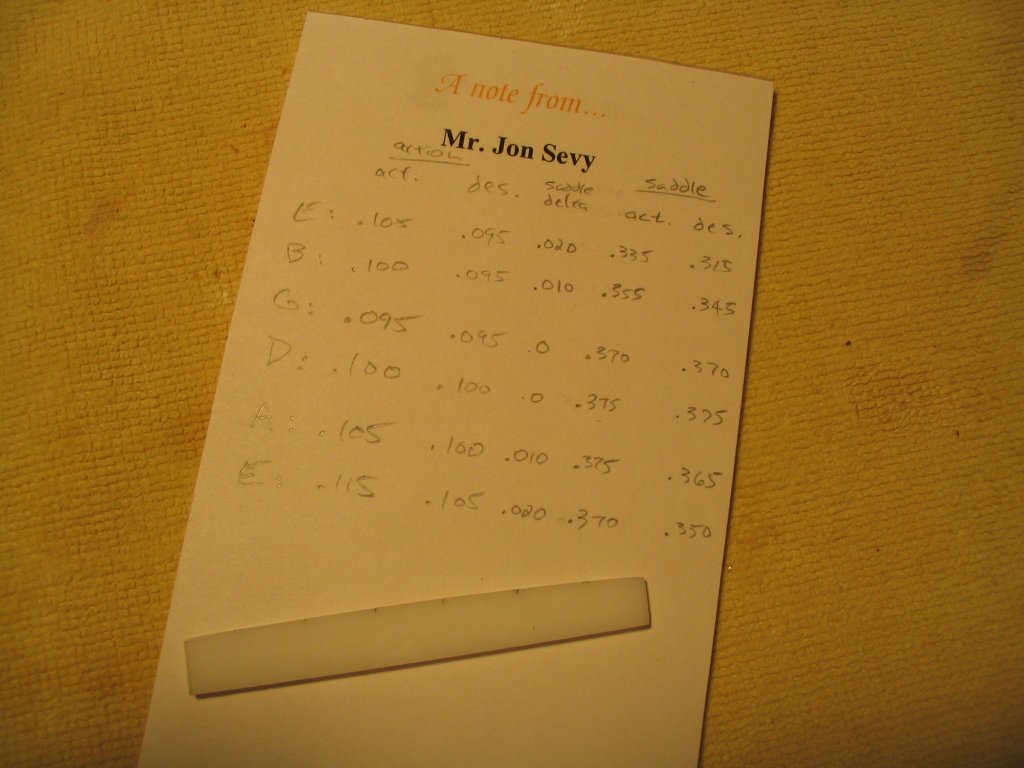

The saddle height is the final element to be adjusted. Note that the saddle provides just the height adjustment for the strings; the positioning of the string holes in the bridge provides the spacing. Thus the saddle does not have slots like the nut does. When the nut slot depths and relief have been set as desired, the action is controlled entirely by the saddle height. The action is the height of the strings above the frets, and is typically measured at the 12th fret, halfway between the nut and saddle. The action can be measured using a calibrated wedge; the wedge sits on the 12th fret, and slid under the string as the string is gently plucked until the string contacts the wedge, at which point the action (the height of the string above the fret) can be read from the surface of the wedge. In the photo below, the high E string action reads .105″.

The action should be adjusted to accommodate the owner’s playing style. As with relief, a lower action is best suited for softer playing and solo work, while a higher action is needed for a harder playing style to avoid string buzz. The action is usually set lower on the higher-pitched (smaller diameter) strings than on the lower-pitched strings to account for the lower strings’ tendency to vibrate with greater amplitude. A general range of action settings at the 12th fret is

- High E: .085″ – .095″

- Low E: .100″ – .115″

with the strings in between having actions between those of the outer strings.

To lower the action, the saddle height is lowered. However, because the action is measured halfway between the nut and saddle, the reduction in action will be half the reduction in saddle height, or equivalently, the saddle height must be reduced by twice the amount it is desired to reduce the action. For example, suppose the action on the high E string is desired to be .085:, and that it initially measures .100″. The action for this string is thus desired to be lowered by .015″; this then requires that the height of the saddle at the position of this string be lowered by twice this, or .030″. The equivalent calculation is done for each string.

The strings are loosened and the saddle is removed from its slot in the bridge. The height of the saddle at each string position is measured, and the desired height is calculated from the action measurements. A bone saddle blank is then marked with the desired height at each string position.

The saddle is cut to the marked profiles, and then rounded on top. When the saddle is reinstalled, the strings should all have the correct action.

Interactions

The action and relief settings are not completely independent; adjusting either can affect the other. Tightening the truss rod to reduce the relief will also generally lower the action, because the force of the truss rod pulls the neck back and thus tends to make the strings lie closer to the fretboard. Conversely, if the action is lowered by lowering the saddle height, the strings will lie closer to the surface of the fretboard and thus have less leverage to put a bow into the neck, reducing the relief. Thus if either the action or relief is adjusted, the other should be checked to make sure it has not changed significantly.

Truss Rod Cover

When the neck relief is in adjustment, the cover for the truss rod adjustment nut can be fabricated and installed. The cover can be secured with 3 small brass screws, or magnetically, as described in another article.

Pickguard

The final step in finishing the guitar is to fashion and affix a pickguard. The pickguard can be made of pretty much any thin hard material that will protect the soft spruce top from errant pick strokes. I use self-adhesive clear plastic from a lutherie supplier. The plastic is cut to size and pressed to firmly to attach it to the top.

Appendix: Making a Truss Rod

While I now purchase pre-made two-way truss rods, the following shows how to make the one-way rod that I previously used. Though it only provides one-way neck adjustment (back bending), the design is ingenious and pretty much foolproof, and not too difficult to make. I believe the original concept is attributed to luthier Michael Gurian. Like the commercial rods, the rod is not glued into the neck, so is easily removable if there are ever problems (which I’ve never had), and applies just a pure bending moment to the neck without any compressive forces as in earlier “bent rod” designs. The theory of operation is quite simple. If you have two bars attached at the ends, one above the other, and you shorten the bottom bar but not the top, then the two-bar assembly is going to bend itself downward to form an arch. If this assembly is inside a guitar neck, it will try to push the neck into this arch as well.

The rod consists of a piece of 3/16″ steel rod, threaded at one end, doubled back on itself, and installed into a special brass end block with a brass nut. The photo below shows the brass end block. This consists of a 1/2″ brass cube that has two 3/16″ holes drilled right next to one another. The only thing special is that one of the holes is “stopped” – it doesn’t go all the way through to the other side of the block, but stops about 1/8″ from the end. The photos below show the two sides of the block; note that the “stopped” hole has just the 1/8″ pilot hole going through.

A 3/16″ steel rod is then threaded about 1″ on one end, and then bent back on itself. The length of the rod is chosen so the bent rod will fit into the slot routed into the neck; the rod should go about to the end of that slot. I usually find the slot is about 13″ long, so I use a rod about 26″ long. When doubled-over, the unthreaded end of the rod should be about 3/8″ or 1/2″ shorter than the threaded end.

The rod is then wrapped diagonally with fiberglass-reinforced packing tape to hold the two rods together when tension is applied to the nut.

The doubled-over rod is then inserted into the brass end block, with the threaded end going through the “through” hole and the unthreaded end going into the “stopped” hole. The threaded portion is longer, and should stick out about 1/4″. A small flat is then filed onto the brass end block so it won’t stick up above the angled peghead surface when it is installed (see following photo).

The completed rod can then be inserted into the truss rod slot in the neck. Note that due to the brass end block, the truss rod groove needs to have a secondary 1/2″ wide slot cut to accommodate the end block. The friction of the tape should keep it from falling out before the nut is tightened; once the nut is tightened to counteract the string force the rod will wedge itself tightly against the neck slot as it tries to bend itself backwards. Note the small angled flat on the end block that keeps the block from protruding above the surface of the peghead.

Previous: Fretting |

Next: The result |